YHMT-A+A+A+ IV Tester Precision Solar Panel Testing For Modern PV Production Lines

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Lamp Spectrum | IEC60904-9 | Light Intensity | 1000W/m² |

|---|---|---|---|

| Light Intensity Non-uniformity | ≤±2%[AAA] | Instability Degree Of Irradiation | ≤±1%[AAA] |

| Test Results Consistency | ≤±0.05%[AAA] | Test Error Of Electrical Properties | ≤1% AAA |

| Highlight | Precision Solar Panel Tester,YHMT-A+A+A+ IV Tester |

||

![]()

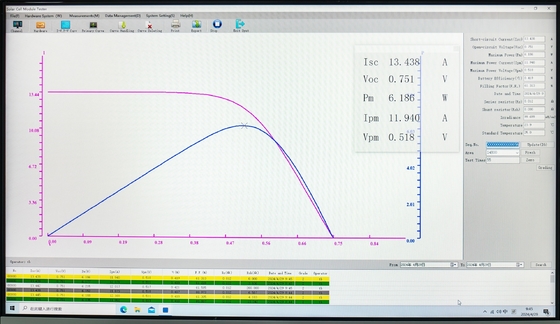

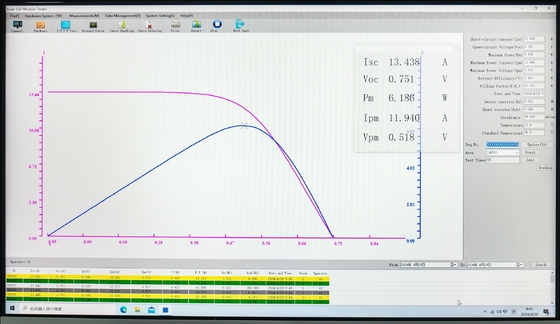

Solar Module IV Tester

- Equipment Model: YHMT-A+A+A+

- Equipment Purpose:

This IV Tester is designed for the automatic IV curve measurement of monocrystalline and polycrystalline solar modules. It serves as a critical component in a modern Solar Panel Production Line. By integrating Hight-Efficiency IV Testing technologies, the IV tester meets the high demand of current photovoltaic manufacturing. Moreover, the IV Tester supports IV Curve Measurement for precise analysis.

![]()

Main Technical Indicators and Principles:

Simulation Light Source

3.1.1 Spectral Matching: The range of the IV Tester meets the IEC60904-9 spectral irradiance distribution requirements (AM1.5).

3.1.2 Total Irradiance: 100 mW/cm²

3.1.3 Irradiance Adjustment Range: 20 mW/cm² to 120 mW/cm²

3.1.4 Irradiance Uniformity: ±1%

3.1.5 Irradiance Instability: ±0.5%

3.1.6 Single Pulse Duration: 60 ms

3.1.7 Flash Count Function: Flash count and reset function after replacement.

3.1.8 Xenon Lamp Lifetime: 300,000 cycles (Germany).

3.1.9 Irradiance Direction: Vertical upward emission.

3.2 IV Curve Measurement Range:

3.2.1 Effective Test Area: 2000mm × 1200mm

3.2.2 Effective Test Range: 5W to 700W (maximum module power area).

3.2.3 Measurement Voltage: 0 mV to 200V (resolution 1 mV).

3.2.4 Measurement Current: 0 mA to 20A (resolution 1 mA).

3.2.5 Ambient Temperature: 15°C to 35°C.

3.3 Measurement Accuracy:

3.3.1 Measurement Inconsistency: ±0.5%

3.3.2 Measurement Error: ±1%

3.4 Measurement Method: Four-wire measurement

3.5 IV Curve Measurement Parameters: Isc, Voc, Pmax, Vm, Im, FF, EFF, Temp, Rs, Rs

3.6 Measurement Interval: 5 seconds

3.7 Data Collection:

The equipment collects I-V and P-V curves with 8000 data collection points using state-of-the-art IV Curve Measurement techniques. This integration ensures that the IV Tester supports Hight-Efficiency IV Testing and provides precise diagnostic data in a Solar Panel Production Line.

3.8 Test Condition Calibration:

3.8.1 Irradiance Auto Compensation

3.8.2 Temperature Auto Compensation

3.9 Temperature Measurement:

3.9.1 Temperature Compensation and Display

3.9.2 Built-in Non-contact Infrared Temperature Measurement

3.10 Test Results:

3.10.1 Voice Reporting and Prompt for Test Results

3.10.2 Display Test Time and Graphical Parameters (I-V Characteristic Curve)

3.11 Test Report:

3.11.1 The current working interface displays and records the I-V characteristic curve via integrated IV Curve Measurement.

3.11.2 The main test parameters of all modules can be saved to a specified file on the hard disk.

3.11.3 The specified file can be named by the user.

3.12 Data Summary and Printing:

3.12.1 Data summary can be performed based on the set time period or anytime.

3.12.2 Print in Excel format (including cumulative I-V characteristic curve output).

3.13 Dedicated Software:

3.13.1 Input of Temperature Compensation Coefficient

3.13.2 Input of Date, Name, and Row Numbers

3.13.3 Auto-increment of Serial Number Starting Point

3.13.4 Defective Product Parameter Range Setting

3.13.5 Parameter Centralized Control

3.14 Working Time: The IV tester can operate continuously for more than 24 hours.

Equipment Configuration:

4.1 Test Host (including electronic load): 1 unit

4.2 Light Source (including optical system): 1 set

4.3 Computer: 1 unit

4.4 High-Speed Data Acquisition A/D Card: 1 unit

4.5 Dedicated IV Curve Measurement Software: 1 set

4.6 Standard Battery (for irradiance calibration and uniformity IV curve measurement)

Features:

Power Supply: Mingwei

Control System: Siemens PLC

Xenon Lamp: German Heimann

Touchscreen Operation: Weilin

Voice Reporting: Supported

Our Services:

![]()

About Us:

Yoha Solar is a high-tech enterprise dedicated to the research, development, manufacturing, sales, and after-sales service of serial photoelectric automation equipment.

15+ Years Engaged In Solar

300+ Customers Worldwide

![]()

Our company primarily serves the solar photovoltaic industry and holds its own import and export rights. We have developed a range of independent R&D equipment.

Main Machinery:Fiber Laser Cutting Machine

Solar cell sorting Machine

Solar Cell IV tester

EL defect tester

EL and AOI Appearance Tester

Solar Panel Production Line

Other Auxiliary Machines