Precision IV Testing Machine For Solar Production Lines ±0.5% Consistency 300K Flash Life Auto Temp Irradiance Compensation 2400*1400

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Lamp Spectrum | IEC60904-9 | Light Intensity | 1000W/m² |

|---|---|---|---|

| Light Intensity Non-uniformity | ≤±2%[AAA] | Instability Degree Of Irradiation | ≤±1%[AAA] |

| Test Results Consistency | ≤±0.05%[AAA] | Test Error Of Electrical Properties | ≤1% AAA |

| Highlight | Precision IV Testing Machine,IV Testing Machine |

||

Solar Panel IV Tester

![]()

![]()

Overview of Solar Module Tester

The Solar Module Tester is a highly reliable and high-precision testing device designed for solar cells. It uses high-power, long-lifetime imported pulsed xenon lamps as the light source, an imported ultra-high precision four-channel synchronous data acquisition card for data collection, and a professional ultra-linear electronic load to ensure precise test results. It is suitable for use by solar photovoltaic module manufacturers for sorting and analyzing solar cells.

Specifications

Main Test Indicators

- Maximum Measurable Module Size: 2400mm × 1400mm

- Light Source: High-energy pulsed xenon lamp

- Light Intensity Adjustable Range: 20—120W/C㎡

- Xenon Lamp Lifespan: ≥300,000 cycles

- Light Intensity Uniformity: ±2%

- Measurement Range and Accuracy:

- Voltage: 0~5 V ±0.1%, 0-30V ±0.1%, 0~60V ±0.1%

Current: 0~2A ±0.1%, 0-20A ±0.1%

- Measurement Error: ≤2%

- Repeat Measurement Error: ±1%

- Standard System Configuration: Horizontal test bench + vertical control cabinet + PC + dedicated testing software

- Power Requirements: 220V/50Hz/2KW

- Weight: 200kg

- External Dimensions:

- Test Bench: 1065 × 1230 × 1970mm

- Control Cabinet: 670 × 610 × 1630mm

Product Features

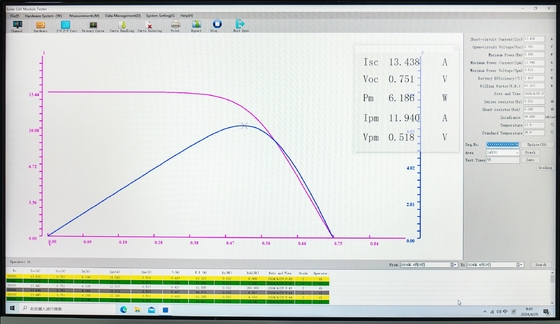

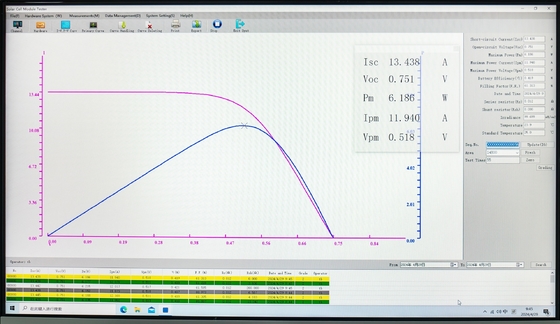

- Measured (Displayed) Parameters:

- I-V curve, P-V curve, Short-Circuit Current (Isc), Open-Circuit Voltage (Voc), Peak Power (Pm), Maximum Power Point Voltage (Vm), Maximum Power Point Current (Im), Fill Factor (FF), Cell Efficiency (η), Test Temperature (T).

- The software also allows the display of current, voltage, and power parameters corresponding to any point on the curve via mouse interaction.

- Professional Linear Scanning Electronic Load: Guarantees measurement accuracy and ensures the linear measurement error within ±2% across the entire measurement range.

- Simplified Software Design: The software is simple to use, with only the correction of relevant coefficients needed during calibration.

- Light Source: Uses the internationally popular pulsed xenon lamp simulator, with a parabolic reflector device to achieve high uniformity of simulated sunlight, avoiding temperature-related test result deviations from steady-state sunlight simulators.

- Imported Xenon Lamp: Ensures the spectral correctness of the light source and long service life.

- Cell Measuring Mechanism: Uses synchronous motor drive, reducing operational noise and minimizing cell damage during testing.

- Voice Reporting Function: Allows relevant measurement parameters to be announced by voice, enhancing measurement efficiency and reducing damage rates.

- Crystalline Silicon Cell Measurement: Uses a four-wire connection to ensure accurate measurements.

- Semiconductor Probe: Measures the temperature of the test cell, ensuring accurate and reliable temperature measurements.

- Short Measurement Intervals: The time interval between tests is less than 5 seconds, enabling fast measurements.

- Human-Machine Interface: The interface is user-friendly, making operation more intuitive.

Environmental Requirements for the Solar Module Tester

- The testing area must be larger than 3m × 5m, with a height of at least 2.5m.

- The room should have an illuminance of less than 100 lux and should be equipped with both heating and cooling air conditioning to stabilize the room temperature around 25℃.

- The power supply should be 220V/2KW, with easy connection, and a reliable grounding system.

- There should be sufficient space for a storage room connected to the testing area, ensuring the temperature of the test cells is similar to the test room temperature.

- The testing room should be equipped with a compressed air source interface. The air pressure should be stable between 5-8 Kg/C㎡.

Our Services:

![]()

About Us:

Yoha Solar is a high-tech enterprise dedicated to the research, development, manufacturing, sales, and after-sales service of serial photoelectric automation equipment.

15+ Years Engaged In Solar

300+ Customers Worldwide

![]()

Our company primarily serves the solar photovoltaic industry and holds its own import and export rights. We have developed a range of independent R&D equipment.

Main Machinery:Fiber Laser Cutting Machine

Solar cell sorting Machine

Solar Cell IV tester

EL defect tester

EL and AOI Appearance Tester

Solar Panel Production Line

Other Auxiliary Machines