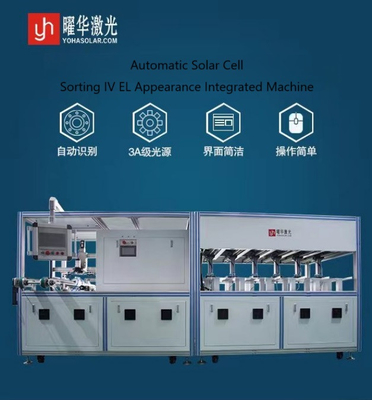

High-Throughput IV EL Sorting Integrated Machine With Advanced IV Testing , EL Testing And Solar Cell Sorting For Solar Panel Production Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Test Size | 230×230mm | Workpiece Specification | 4 Loading Boxes |

|---|---|---|---|

| Ambient Temperature/humidity | 20~40℃/85 RH%u Below | Discharging Station | 24 Discharging Stations (standard Machine) |

| Machine Power Consumption | 3KW | Equipment Size | 4200mm*2000mm*1970mm |

| Highlight | Advanced IV EL Sorting Integrated Machine,IV EL Sorting Integrated Machine |

||

Automatic Cell IV EL Sorting Integrated Machine

![]()

I. About the IV EL Sorting Integrated Machine

-

Equipment Name: Solar Cell EL and Power Automatic Sorting Machine

(This advanced equipment is not only an IV EL Sorting Integrated Machine but also incorporates the latest techniques in IV Testing and EL Testing for automated solar cell evaluation.) -

Model: YH-ZDFX-2400 -- IV EL Sorting Integrated Machine

-

Overall Installation Dimension Diagram:

-

(Refer to the provided diagram for detailed layout specifications – the system is engineered for seamless operation on a high-performance Solar Panel Production Line.)

II. Applicable Cell Information

-

Polycrystalline and monocrystalline solar cells with dimensions ranging from 156mm to 220mm

-

Warpage ≤ 3mm

-

2 to 6 busbars, 9 busbars

-

Flat A-grade cells (with a yield rate of over 98%)

This IV EL Sorting Integrated Machine will be used for testing qualified products.

III. Key Performance and Technical Parameters

-

Capacity:

-

Actual reference operating speed: 2200 pieces per hour

-

Average speed is approximately 1.6 seconds per piece

-

Note: This does not include the time for retrieving and unloading solar cells and changing the loading trays. Speed may be affected by factors such as inspection items and accuracy.

-

-

Breakage Rate:

-

≤ 0.05% (This parameter refers to breakage caused by the machine itself, excluding material breakage.)

-

-

False Judgment Rate:

-

Approximately 6% (The specific ratio will be determined through negotiation depending on Party A’s process and inspection standards.)

-

Calculation: The number of A cells mistakenly judged as B divided by the number of cells selected by the machine.

-

-

Missed Judgment Rate:

-

≤ 0.3% (The specific ratio will be determined through negotiation depending on Party A’s process and inspection standards.)

-

Calculation: The number of B cells missed by the machine divided by the number of cells selected by the machine.

-

Technical Specification Table

| Technical Specifications | Details |

|---|---|

| Equipment Name | Solar Cell EL Automatic Sorting Machine (Offline) – a prime example of an IV EL Sorting Integrated Machine |

| Model | YH-ZDFX-2400 |

| Production Method | Offline Solar Cell EL Testing – integrated with advanced EL Testing capabilities |

| Functions | Conduct EL testing and IV testing and sort the cells |

| Applicable Cells | Monocrystalline / Polycrystalline; Compatible with Half Cells |

| Size | 166×81 to 220×220 mm |

| Cameras | 20 Megapixels (front) for high accuracy EL testing |

| Thickness | 0.16~0.22 mm |

| Tooling Specifications | Feeding: 4 Feeding Trays (2 in use, 2 as spares) Discharge: 32 Discharge Trays |

| Equipment Operating Capacity | Production Capacity: 2000 Pieces/hour (Operation Cycle 1.5 seconds/piece) – ideal for high-throughput Solar Panel Production Line processes |

| Normal Operation Time | ≥ 99% (Excluding planned downtime) |

| MTBF (Mean Time Between Failures) | ≥ 500 Hours |

| MTTR (Mean Time To Repair) | ≤ 1 Hour |

| Power Requirements | Power Supply: AC 220V, 15A; Efficiency: 3KW |

| Compressed Air | 0.6~0.8 Mpa, 300L/min, Air tube outer diameter Φ8mm |

| Environment | Temperature/Humidity: <20–40℃ / 85% RH |

| Cleanliness | Meets the standards of a Class 100,000 cleanroom |

| Noise | ≤ 20 dB |

| Equipment Specification | Total Weight: 800 kg; Size: 32 Discharge Station (Standard Machine): 5500mm(L)×1200mm(W)×2000mm(H) |

| Installation | Installed according to the site location |

| Software | Developed in-house, with free software upgrades available. |

| Components | PLC: Siemens; Slide Block: Hiwin; Cylinders: Airtac, SMC; Solenoid Valves: SMC; Motors: Panasonic, leisai, xinje. |

IV. Inspection Items

-

Non-contact Inspection: Designed to avoid secondary damage during the inspection process.

-

Specific Image Acquisition System: No darkroom is required, ensuring high image quality.

-

High Inspection Efficiency: The system can be embedded in the production line for online inspection, playing a crucial role in IV Testing.

-

Artificial Intelligence Algorithm: Enables automatic defect identification without human intervention.

-

Wide Application Range: Suitable for various types of silicon wafers or solar cells, making it versatile within a Solar Panel Production Line environment.

V. IV EL Sorting Integrated Machine Composition

-

Structural Diagram:

-

(Refer to the structural diagram for full system layout.)

-

-

Material Box:

-

Dual-side alternate feeding. Four material boxes provided, two in use and two as backups, alternating in use.

-

-

Visual Inspection System:

-

Proprietary software system that supports integrated IV Testing and EL Testing functions.

-

-

Automation Inspection Toolkit:

-

High output and precision algorithms for various classification inspections; customer-defined classifications and color difference data.

-

-

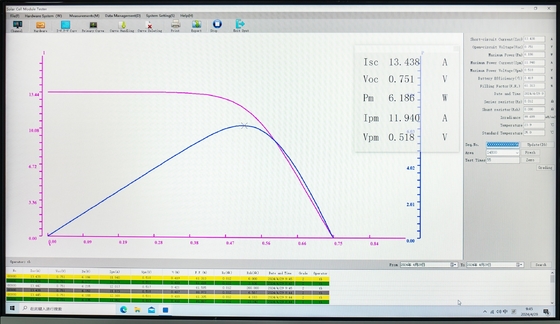

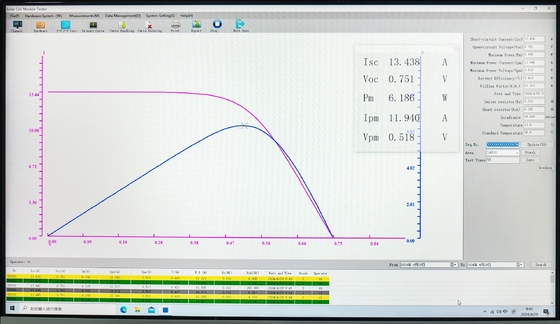

IV Testing:

-

Total Irradiance: 100 mW/cm²

-

Irradiance Uniformity: ≤ ±2%

-

Irradiance Stability: ≤ ±2%

-

Single Irradiation Pulse Duration: 10ms – 60ms

-

Flash Count Function: Flash count with reset function.

-

Xenon Lamp Lifespan: 100,000 flashes

-

Irradiation Direction: Vertical downward emission

-

Measurement Range:

-

Effective Testing Area: 220mm × 220mm

-

Effective Testing Range: 0.1W – 10W

-

Measurement Voltage: 1V (Resolution: 1mV, Range: 1/16384)

-

Measurement Current: 10A (Resolution: 1mA, Range: 1/16384)

-

Ambient Temperature: 15℃ – 35℃ (Resolution: 0.1℃)

-

-

Measurement Accuracy:

-

Repeatability: ±1%

-

Measurement Error: 2%

-

-

Measurement Method:

-

Four-wire measurement, pneumatic buffer contact, front probe contact, back contact.

-

-

Measurement Parameters:

-

Isc, Voc, Pmax, Vm, Im, FF, EFF, Temp, Rs, Rsh.

-

-

Measurement Interval: 5 seconds

-

This IV testing system stands out as a cutting-edge solution for solar cell characterization, combining precision engineering and industrial-grade reliability to deliver unmatched performance in electrical parameter analysis. Its advanced IV testing module is meticulously designed for laboratories and production lines requiring ultra-accurate, repeatable results under controlled conditions

The IV EL Sorting Integrated Machine can be a great choice for your Solar Panel Production Line. It's IV Testing, EL Testing and Solar Cell Sorting can make your Solar Panel Production Line more sophisticated and efficient. It can also function as a Solar Cell Sorting Machine, solar cells are sorted accorting to the IV testing and EL testing.

Our Services:

![]()

About Us:

![]()

Yoha Solar is a high-tech enterprise dedicated to the research, development, manufacturing, sales, and after-sales service of serial photoelectric automation equipment.

15+ Years Engaged In Solar

300+ Customers Worldwide

![]()

Our company primarily serves the solar photovoltaic industry and holds its own import and export rights. We have developed a range of independent R&D equipment.

Main Machinery:Fiber Laser Cutting Machine

Solar cell sorting Machine

Solar Cell IV tester

EL defect tester

EL and AOI Appearance Tester

Solar Panel Production Line

Other Auxiliary Machines