A+A+A+ Certified Solar Cell Tester Single Wafer Sorter & Panel Testing System For PV Manufacturing

| Test Size | 220X220mm | Detection Type | Single Crystal Or Polycrystalline Silicon Wafers And Battery Wafers |

|---|---|---|---|

| Online Detectable Defects | Black Center, Black Edge, Black Mass, Hidden Crack, Crack, Fragment, Low Efficiency Piece, Black Line And Defect Corners, Broken Edges, Etc. | Detection Efficiency | Single Detection Time Is <0.5 Seconds; |

| Highlight | Efficiency Solar Cell Tester,Single Wafer Solar Cell Tester,PV Manufacturing Solar Cell Tester |

||

Solar Cell Sorting & PL Testing System (Model: YHCT-PL)

Functionality:

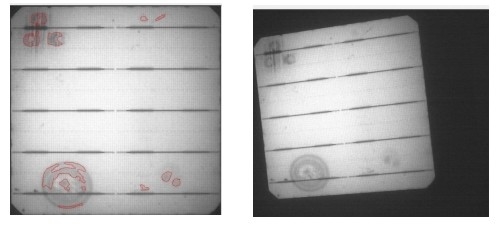

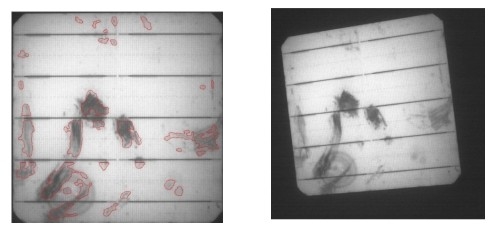

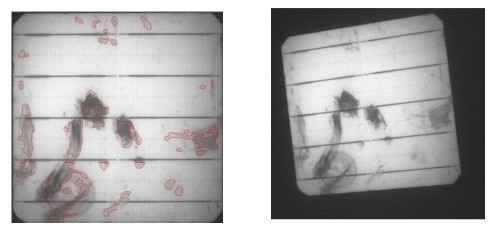

A cutting-edge Solar Cell Tester integrating PL Testing (photoluminescence detection) and AI-driven defect recognition for Solar Cell Testing and sorting. Designed for monocrystalline/polycrystalline silicon wafers and cells, it enables non-contact, high-speed quality control in photovoltaic manufacturing.

Technical Specifications

| Parameter | Specification |

|---|---|

| Test Object | Monocrystalline/polycrystalline cells & wafers (max size: 210×210mm) |

| Detection Speed | <0.5 seconds per test |

| Defect Types Identified | Black center, cracks, low-efficiency cells, hidden cracks, missing corners, etc. |

| Laser System | Adjustable power; 220×220mm laser spot coverage |

| Software | AI algorithms for automatic defect classification; parameterized judgment criteria |

| Integration | Standalone or embedded in production lines via network communication |

| Detection Method | Non-contact PL Testing to prevent secondary damage |

| Compatibility | Pre/post-welding stages; multi-cell simultaneous detection |

Key Features

-

AI-Driven Defect Recognition:

-

Deep learning algorithms automate defect identification (e.g., cracks, black edges) without manual intervention.

-

-

High-Speed PL Testing:

-

Achieves <0.5s detection cycles, ideal for high-volume Solar Cell Testing workflows.

-

-

Flexible Integration:

-

Functions as a standalone Manual Solar Cell Tester or in-line Solar Cell Sorting Machine within production lines.

-

-

Customizable Detection:

-

Adjustable laser power and defect thresholds to adapt to diverse cell types (mono/polycrystalline).

-

-

Non-Contact Precision:

-

Infrared imaging system eliminates physical contact, ensuring zero cell damage.

-

System Components

-

Laser Light Source: Generates uniform 220×220mm square spots for consistent PL excitation.

-

Infrared Camera & HD Lens: Captures high-resolution defect images without darkroom requirements.

-

Detection Software: User-friendly interface with real-time analytics and customizable reporting.

Applications

-

Quality Control: Defect detection in raw wafers, post-processed cells, and final modules.

-

Sorting: Grades cells based on PL Testing results for Solar Cell Sorter integration.

-

R&D Support: Identifies efficiency losses and process flaws in cell manufacturing.

Why Choose Our Solar Cell Sorting Machine?

-

Zero Secondary Damage: Non-contact PL Testing ensures cell integrity.

-

Production-Ready: Seamless integration into existing Solar Cell Testing lines with ≤20ms latency.

-

Future-Proof Design: Software upgrades and modular hardware adapt to new cell technologies (e.g., TOPCon, HJT).

Our Services:

![]()

About Us:

![]()

Yoha Solar is a high-tech enterprise dedicated to the research, development, manufacturing, sales, and after-sales service of serial photoelectric automation equipment.

15+ Years Engaged In Solar

300+ Customers Worldwide

![]()

Our company primarily serves the solar photovoltaic industry and holds its own import and export rights. We have developed a range of independent R&D equipment.

Main Machinery:Fiber Laser Cutting Machine

Solar cell sorting Machine

Solar Cell IV tester

EL defect tester

EL and AOI Appearance Tester

Solar Panel Production Line

Other Auxiliary Machines